Reduced output in March & May in the automotive sector could change the typical activity curve in 2020, with busier summer months ahead to make up for the lost time. Colliers International has just launched its recent research piece “COVID-19 & Industrial Production – The Spring Relevance” where it discusses the importance of particular months for the manufacturing sector in the EMEA region as well as presents the outlook for the coming months.

Soon after the COVID-19 outbreak, a good share of manufacturing facilities across Europe, as with many other businesses, ceased operation to help protect employees from the spread of the virus and also as a means of countering the expected drop in demand going forward. The majority are now back up and running, but some are operating at a reduced capacity to respect health and safety guidelines for one, but also in some cases due to a drop in demand for certain goods and products, a build-up of inventory, or are awaiting materials and components as supply chains come back online.

Kevin Turpin, Regional Director of Research | CEE, explains: “In terms of production activity over the spring months, we have analyzed how important the currently affected March-May period is for the industrial sector throughout the EMEA region. While huge parts of the EMEA economies were shut down like switching off a light, it is clear that restarting operations gradually in the subsequent months will mean the full recovery of lost business will take a fairly long period of time (at least a year, if IMF economic growth forecasts become reality)”.

European production cycles are extremely in tune with one and other. With a few exceptions, October and November stand out as either the first or second most relevant months for most countries we analysed. Looking at the heat-map, March and the May-July period also stand out as quite relevant.

The relevance of March and May for production sector

After gauging risks and adapting operations to new realities (also incorporating health and safety regulations), many operations have been restarted as of May 2020, though may not be at full capacity. Either way, this situation may well hold significant implications for the real estate sector as well, but for now, it is still too early to say where this will all land. Some companies have lost out on some of their most lucrative months.

March and May are two of the biggest production months over the course of the year – March is the second biggest month for output in Italy, Spain and Czechia and the biggest for Germany, UK, Belgium and Austria. Fortunately, April is of less importance in terms of production output due to the Easter holidays.

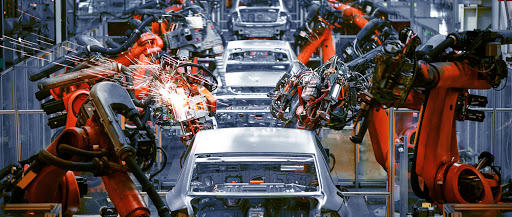

The busiest months for the automotive sector

For the automotive sector, which is one of the staples of European industry and generates close to 1 in every 10 jobs in manufacturing directly, March is the busiest month of the year for some of the continent’s biggest producers – Germany, France, UK, Poland and Romania. For Spain and Italy, May is the biggest month in the automotive industry. Faced with having to catch up on reduced output in March & May, this could change the typical activity curve in 2020, with busier summer months ahead to make up for the lost time. The risk of a second COVID-19 wave is very real, so producers will need to mitigate against this and the subsequent risk that output is curtailed during the peak output months of October-November.

Outlook

Generally speaking, while the spring period is quite important, (except April or the Easter month) the October-November period is by far the most active. This means that any potential second COVID-19 wave hitting production activities during late autumn-early winter months maybe even more significant. Although nobody can forecast this, it is a risk scenario worth considering, particularly given how big these months are. Consequently, we would expect production activities to be adapted via increased output in summer months, with companies maybe stockpiling more inventories than they would normally like and maybe increasing the need for more flexible leasing arrangements during these challenging times and going forward.

Silviu Pop, Head of Research, Colliers International Romania, adds: “The new reality of higher inventories may lead to a somewhat higher need for short-term storage options, though the longer-term picture is for sure, less clear, amid diverging trends.”

In addition, the situation caused by the pandemic can motivate companies to search for warehouse locations near their production plants.

“In Poland, we still observe interest from manufacturing companies to invest in our region to “shorten supply chains”. This approach can increase investments in the CEE countries, especially in Poland, which has a very large supply of investment land, access to employees and an excellent location,” says Maciej Chmielewski, senior partner, director of Industrial and Logistics Agency at Colliers International.